Aerosol leak detectors – a true micro-leak detection process, constructed to comply with the FEA guidelines laid out in their “Alternative Method” and the BAMA recommendations.

The process of the aerosol micro leak detection machines works with all widely used propellants including inert gasses and is available in two versions:

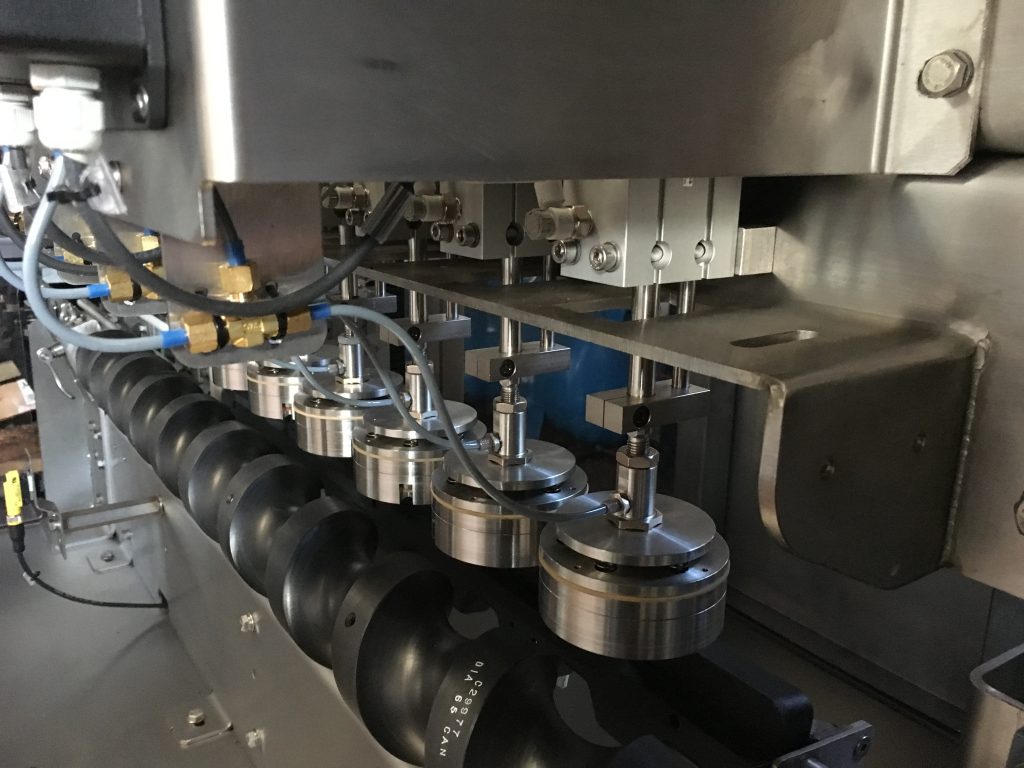

Crown Micro-Leak detection machines – The aerosol valve and valve crimp area are enclosed in a vacuum chamber and tested to an adjustable setpoint. The Crown detector typically only processes tinplate aerosol containers, or aerosol containers with a definite upper shoulder. For aluminium and plastic aerosol containers, a Full-Body aerosol Micro-Leak Detector machine would be necessary.

‘Full-Body’ Micro-Leak Detection machines – The entire aerosol container is enclosed in a vacuum chamber and tested to an adjustable setpoint. The Full-Body detector can process any shape, material, or construction of aerosol, making it a fully versatile aerosol leak detector.

Aerosol containers are tested in isolation to the ADR 2007 requirement of a leak rate no greater than 2.0 x 10-3mbar.l.s-1 at an ambient temperature of 20°C. Any containers leaking at a rate higher than this will be marked by the aerosol leak detector as failures.

If a container fails the test, the aerosol micro leak detection machine can:

- Stop, and indicate the failure for operators to remove, before restarting the Machine.

- Push the failure into a customer-provided ‘Bin’ which would be situated underneath the conveyor.

- Push the failure onto a separate ‘Reject Conveyor’.

Both the Bin and Reject conveyor would require periodic inspection to ensure they did not fill to capacity.